3M™ Corrosion Prevention Sealing Tape 9143FR

- 3M ID B5005378019

3M™ Aircraft Interior Corrosion Prevention and Protection Tapes are designed to help reduce maintenance costs and increase service life of aircraft interior floor systems.

-

The floors of aircraft entryways, galleys, lavatories and cargo compartments are vulnerable to frequent sources of moisture. Fluids from spills and leaks can migrate into the underlying floor support system, and condensation can form on sub-floor structures which can lead to corrosion. The resulting corrosion damage can weaken the entire sub-floor structure and result in costs up to $100,000 per aircraft, in addition to downtime.

Details

Highlights

- Excellent corrosion resistance

- Flame Resistant per 14 CFR 25.853 (a), Appendix F, Part I (a) (1) (ii), 12-second vertical burn1

- FAA PMA approved

- Helps to protect floor panel metallic support structures from corrosion caused by exposure to fluids in the cabin environment

- Exceptional shop handling

- Cuts easily with scissors or common shop tools

- Repositionable during application

- Easy removal after service with little or no residue

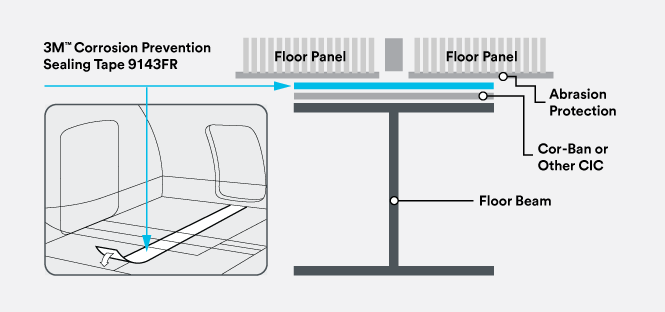

3M™ Corrosion Prevention Sealing Tape 9143FR is a corrosion protection tape that provides a sealing layer between aircraft floor beams and floorboards. When applied to aluminum floor beams and other floor support structures, it helps to protect the metallic support structure from the effects of repeated exposure to fluids. A 43 mil tape, 9143FR offers corrosion resistance for interior aircraft applications, particularly around doors, galleys, lavatories and in the cargo compartment.

-

Corrosion Resistance

Corrosion Resistance -

Easy Removal And Application

Easy Removal And Application -

Exceptional Shop Handling

Exceptional Shop Handling -

Flame Resistance

Flame Resistance

-

Do more for your aircraft floors

The floors of aircraft entryways, galleys, lavatories and cargo compartments are vulnerable to frequent sources of moisture. Fluids from spills and leaks can migrate into the underlying floor support system, and condensation can form on sub-floor structures which can lead to corrosion. The resulting corrosion damage can weaken the entire sub-floor structure and result in costs up to $100,000 per aircraft, in addition to downtime.

-

Specifications

Details

| Adhesion Strength (Imperial) | 27 oz/in |

| Adhesion Strength (metric) | 30 N/100mm |

| Adhesive Type | Low Peel FR Acrylic |

| Applications | Corrosion Protection, Surface Protection |

| Backing Material | Polyester |

| Brands | 3M™ |

| Features | Flame Retardant |

| Maximum Operating Temperature (Celsius) | 82 ℃ |

| Maximum Operating Temperature (Fahrenheit) | 180 ℉ |

| Minimum Installation Temperature (Celsius) | 15.0 Degree Celsius |

| Minimum Installation Temperature (Fahrenheit) | 60.0 Degree Fahrenheit |

| Minimum Operating Temperature (Celsius) | -40 ℃ |

| Minimum Operating Temperature (Fahrenheit) | -40 ℉ |

| Product Usage | Aircraft Lavatories, Aerospace, Aircraft Galleys, Aircraft Cargo Compartments |

| Tensile Strength (Imperial) | 36.0 lb/in |

| Tensile Strength (metric) | 630 N/100mm |

| Total Tape Thickness without Liner (Imperial) | 43 mil |

| Total Tape Thickness without Liner (metric) | 1.09 mm |

Resources

Data Sheets

(PDF, 356KB)

Connect with us. We’re here to help.

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email

An error occurred.

Frequently asked questions

Is 9143FR used in the same application as a typical gel tape product?

Is this product flammability resistance rated for use in aerospace fly-away applications?

Is 9143FR FAA PMA approved?

Does this product leave tape residue when removed after the service life?

Can you cut this product with scissors?

Do you have 3,000 hour salt spray testing results?

Which aircraft models is 9143FR FAA PMA approved for use on?

Disclaimer

1 Tested in accordance with 14 CFR 25.853 (a), Appendix F, Part I (a) (1) (ii), 12-second vertical burn per FAA Policy Statement PS-ANM-25.853-01-R2, Reference 21, Option 1 (in a stand-alone mode, cut tape sample of nominal size: 3” x 12”) and FAA Policy Statement PS-ANM-25.853-01-R2, Reference 21, Option 3 (bonded to a worst case substrate). Installation approval is the responsibility of the design approval holder or the aircraft owner/operator.

3m-corrosion-prevention-sealing-tape-9143fr-technical-data-sheet.pdf

3m-corrosion-prevention-sealing-tape-9143fr-technical-data-sheet.pdf 3M™ Corrosion Prevention Sealing Tape 9143FR

3M™ Corrosion Prevention Sealing Tape 9143FR 3M™ Polyurethane Protective Tape 8663DL

3M™ Polyurethane Protective Tape 8663DL 3M™ Polyurethane Protective Tape 8657DL, Translucent White, Flame Retardant, Dual Liner, 24 in x 36 yd, 1 Roll/Case

3M™ Polyurethane Protective Tape 8657DL, Translucent White, Flame Retardant, Dual Liner, 24 in x 36 yd, 1 Roll/Case 3M™ Polyurethane Protective Tape 8658DL, Transparent, Flame Retardant, 4 in x 36 yd, 2 Rolls/Case

3M™ Polyurethane Protective Tape 8658DL, Transparent, Flame Retardant, 4 in x 36 yd, 2 Rolls/Case