(soft, bright music plays)

3M logo. Science. Applied to Life.? Text on screen: Enabling new levels of design with tapes. An

aerial view of a bridge spanning a countryside landscape.

VO: Cars are undergoing a fairly dramatic change.

We're transitioning from a hundred years of internal

combustion engines to electric vehicles.

Several cars drive on the bridge. The sun shines on an electric vehicle with a charger cable

plugged into the charging port. Text: Joel Sabean, 3M Global R&D Lab Leader. Joel Sabean sits in

a lab room and addresses the camera.

VO: My name's Joel Sabean, I'm an R&D director

for the Automotive and Aerospace division. I have been

with 3M for going on 34 years. 3M's a fantastic place to

work for anyone that is curious.

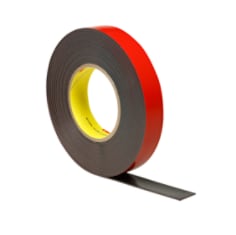

Two rolls of red 3M robust sealing tape of different widths on a table. The center band of a roll

of tape reads: 3M Acrylic Foam Tape.

VO: 3M has been a part of adhesives development in

automotive since the 1970s. We started out with

specialized products that have grown over time.

A close-up of the spoiler of a red car.

VO: Now we have hundreds of variants of adhesives that

enable attachment of many different types of parts to

cars.

A roll of 3M robust sealing tape and an object with tape adhered to its sides.

VO: In the past, they were all mechanically attached,

and we continue to grow that portfolio.

A man walks down a hallway guiding a white car door on a utility cart. The man turns at the end of

the hallway.

VO: Adhesives can be applied to the entire perimeter or

surface of a part and that enables the parts to

experience stress over a wide area and enables a clean

aesthetic that consumers like to see and OEM designers

like to deliver. We consider adhesives as an enabler for

clean design.

A curved metal car part spins to show all sides. Joel addresses the camera.

VO: A fundamental advantage of adhesives is to allow

the attachment to exist in a curved area, in tight spaces

where attaching the part mechanically may make it very

difficult to install. So this is part of offering design

freedom to our OEM customers.

Metal car frames move along a conveyor belt. Yellow robotic arms weld small sections of the car

creating blue sparks. Joel addresses the camera. A length of rubber padding with 3M robust

sealing tape along its side.

VO: OEMs, many times, will develop a foundational

vehicle that they would like to modify for different markets

or, over time, change the appearance of to keep its look

fresh. Because we're attaching the part adhesively, a

new part can go in the same place as an existing part

and the appearance can be updated.

A time lapse of traffic on several highways.

VO: One of the challenges, as the industry has increased

the use of adhesives, is the lack of understanding when

you've successfully applied the part.

A man wearing protective glasses observes a machine pulling two objects apart. An adhesive

between the objects stretches and breaks.

VO: Attaching an adhesively-backed part is as simple as

a mechanically-attached. It comes down to two simple

things: a clean surface and consistent pressure.

The man presses a button on a screen. Joel holds the objects in his hands. The man addresses

Joel and smiles. Joel nods at the man.

VO: 3M supplied materials and tools to make those two

processes clean and simple and over time that has

proven to be effective and reliable. Features include

toughened liners, process liners, that allow the

application of our adhesives to be automated.

Joel addresses the camera. Video footage of a red car driving through a city and tunnels at night.

VO: With the experience of 50 years in attaching

automotive parts to vehicles, 3M has developed

laboratory tests to quantify the strengths of our tape and

correlate them to the mechanical actions that parts

experience on vehicles.

An external view of the driver's side of a red car. The man guides the white car door into a room

with a blue light and a vapor mist. The door closes behind him.

VO: This allows us to quantify the strength of our existing

products and provide confidence to our OEMs that a new

product enables them to consider attaching something

that maybe in the past they could not.

A close-up of weights hanging by hooks on a machine.

Two rolls of the 3M robust sealing tape and a 3M box on a table. Joel and the man wearing

protective glasses walk together in a hallway.

VO: It enables them to open their eyes to various ways to

design a car, to assemble a car, change the look. We

consider ourselves a partner with them and our adhesive

continually evolves and improves their ability to change

and improve how those vehicles are assembled.

Text: Learn more about driving innovative design with tape. Go to 3M.com/rethinkattachment. 3M

logo. Science. Applied to Life.? ? 3M 2022. All rights reserved. 3M is a trademark of 3M.