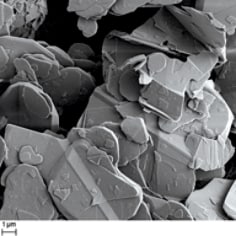

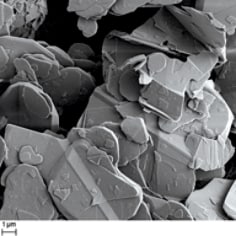

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

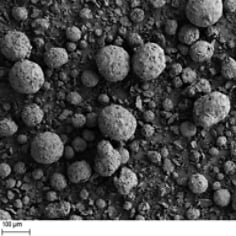

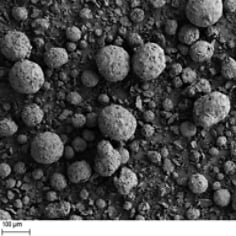

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

3M™ Boron Nitride Cooling Fillers for thermally conductive and electrically insulating plastics and adhesives.

3M™ Boron Nitride Cooling Fillers (3M BN cooling fillers) increase the thermal conductivity of resin compound formulas. Even in small quantities, 3M BN cooling fillers can increase the thermal conductivity of finished components by 50 to 100%. But that’s just the start. 3M BN cooling fillers are also electrically insulating. They can withstand the pressures and temperatures of injection molding. And, because they can be added without significantly altering volume loadings, they can boost the thermal conductivity of existing compounds, help reduce filler usage and potentially lower compound costs. These capabilities mean much more than just thermal efficiency. They enable much broader uses for plastic resin-based parts – and ideal solutions for industries such as communications infrastructure (US, ENGLISH) and automotive OEM where light weight, electrical insulation and controlled viscosity are important.

3M BN cooling fillers can be used for :

Want to talk to a 3M expert to discuss your specific needs?

With a material thermal conductivity of 400 W/m·K in plane, 3M BN cooling fillers can boost the thermal conductivity of polymers by 2-8x compared to alumina fillers.

3M BN cooling fillers provide >10¹⁵ Ohm·cm electrical resistivity with a high breakdown strength.

As 3M BN cooling fillers are among the least abrasive fillers used in plastic compounds, they can help minimize equipment wear and may help extend equipment life. They are available in multiple grades for excellent viscosity control.

3M BN cooling fillers are lightweight (2.25 g/cm³ density) can enable compound densities of 1.2 – 1.6 g/cm³.

3M BN cooling fillers are compatible with many other fillers. This makes them excellent as a secondary filler to “boost” the isotropic thermal conductivity of finished materials. Consider the compound shown here, containing 40% aluminosilicate filler. Simply by reducing aluminosilicate to 30% and adding 10% of 3M BN CF, the thermal conductivity of the compound goes up by 50-100% - without altering overall filler volume loadings and without significantly affecting other performance factors in finished parts.

Learn more about boosting with 3M™ Boron Nitride cooling fillers (PDF, 98.7 KB)

There are many good reasons why plastics are the favorite materials of modern designers, including their relatively low cost, suitability for high volume production, and the exceptional design freedom which they allow.

The utilisation of many plastics is, however, limited as modern electronic components require polymers that effectively dissipate heat in a confined space. Although conventional plastics are not thermally conductive, adding thermal fillers efficiently resolves this shortcoming.

Looking at the landscape of potential thermal fillers, boron nitride is the electrically insulating filler with the highest thermal conductivity.

It is 8 - 20 times more thermally conductive than alumina fillers (intrinsic) and 2 - 8 times more thermally conductive when mixed in polymers.

Today’s plastic compounds often contain a variety of additives to adjust factors such as mechanical properties (e.g. glass or mineral fibers), flame retardancy (e.g. aluminum hydroxide), weight (e.g. 3M™ Glass Bubbles) and cost (e.g. aluminum hydroxide or talcum). The thermal conductivity of these compounds is typically low and can be drastically increased by introducing small amounts (1-10 wt.%) of 3M Boron Nitride Cooling Filler Flakes into the existing compound.

Using a combination of particles having differing geometries creates a complex network in the polymer. Thanks to their unique size and shape, 3M Boron Nitride Cooling Filler Flakes as a secondary filler can build bridges between other fillers.

This favors percolation, less interfaces between the filler and the polymer, significantly increased compound thermal conductivity and enhanced z-direction heat dissipation.

The example on the left (3M lab research) shows how the thermal conductivity of an epoxy potting resin containing aluminosilicate can be increased by the addition of 3M Boron Nitride Cooling Fillers CFF 500-3 as a secondary filler.

In customer tests, boosting in epoxy potting resins already started at 1 wt.% addition of 3M Boron Nitride Cooling Filler Flakes. With < 10 wt.% of 3M Boron Nitride Cooling Filler Flakes 200-3 for example, thermal conductivity increases from 1 to 2 W/mK. The boosting effect has also been observed in a variety of other polymers.

Because of the anisotropic behavior and aspect ratio of 3M Boron Nitride Cooling Fillers, the through-plane thermal conductivity of injection molded polymers depends strongly on the injection parameters.

Boron nitride flakes commonly orient in parallel to the injection direction due to the friction towards the mold.

Orientation in the middle zone of the injection molded part can, however, be influenced by the injection molded parameter.

3M Boron Nitride Cooling Filler Agglomerates and Flakes are platelets compacted to larger aggregates.

The best results in thermal conductivity are obtained when shear forces during the compounding process are limited.

To achieve low shear and soft compounding, it is important to use low rotational speeds.

We also do not recommend using kneading blocks on 3M Boron Nitride Cooling Filler Agglomerates and Flakes.

Lower rotational speed in addition with the suppression of kneader blocks enable the highest thermal conductivities.

3M BN cooling filler platelets are excellent for higher in-plane thermal conductivity. They create relatively simple, direct heat paths that spread heat across the plane surface.

3M BN cooling filler flakes help strike a balance of in-plane and through-plane conductivity. They contain platelets which more randomly oriented vs. when used by themselves. Flakes are also ideal for boosting.

3M BN cooling filler agglomerates deliver very high through-plane conductivity to compounds and parts. They contain platelets which are randomly oriented, creating isotropic thermal conductivity within the polymer for excellent heat dissipation.

Recent initiatives in the electrical and electronics industry have demonstrated that plastics incorporating 3M Boron Nitride Cooling Fillers can help save costs, improve product performance and expand design opportunities.

Because it is electrically insulating, the boron nitride filled compound can be directly injection-molded around printed circuit boards, functioning as both a heat sink and reflector. By decreasing the number of components and enabling one-step manufacturing, total system costs were reduced by 30 %, compared with previous solutions that use metal housings. At the same time, excellent heat management extends the lifetime of the LED.

The following example shows a solution for a new LED flashlight that brings together TIMs, secondary heat sinks – and even the reflector – while simplifying the overall construction.

Conventional unfilled polymer

Thermally conductive polymer

3M™ Boron Nitride Cooling Fillers Platelets (PDF, 1,667 KB)

3M™ Boron Nitride Cooling Filler Agglomerates (PDF, 1,720 KB)

View and download guides for using 3M BN cooling fillers for extrusions, injection molding and more.

Silicone rubbers processing guide (PDF, 137 KB)

Extrusion compounding for injection molding processing guide (PDF, 173 KB)

Injection molding processing guide (PDF, 205 KB)

Want to talk to a 3M expert to discuss your specific needs?

CONNECT WITH A 3M EXPERT

An error has occurred while submitting. Please try again later

Your form was submitted successfully

Filter

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000